OUR PRODUCTS

Powerful clamping at every position

We are your all-around technology supplier for a variety of clamping purposes at forming machines. Stationary, manually movable and self-traveling die clamps as well as clamping systems for moving bolsters and for the coupling of rails on transfer presses – with BERG products our customers are always well advised in terms of optimizing set-up times and ensuring productivity in their press shop.

APPLICATION

The mechanical clamping system PSP 170 AM is used for manual clamping of top and bottom dies with clamping slots on press slides and tables. Optionally, this system is also available for tools with clamping flange (BERG product type PSP-C...AM).

BENEFITS

- Lowest installation costs

- Easy handling and operation

- Permanent and easy clamping status detection

- High safety grade due to self-locking clamping gear

- Easy to retrofit

APPLICATION

Hydraulic and manually movable clamping systems of type BKZ are particularly suitable for clamping top and bottom dies with clamping slots on press slides and tables. This system is also available for tools with clamping flange (BERG product type BKZ-C).

BENEFITS

- Adjustable and fixable T-slot bolt for a wide range of different die flange heights

- Easy to retrofit

- Space-saving thanks to compact design

- Optionally available balancing cap allows use of non-parallel tool clamping surfaces

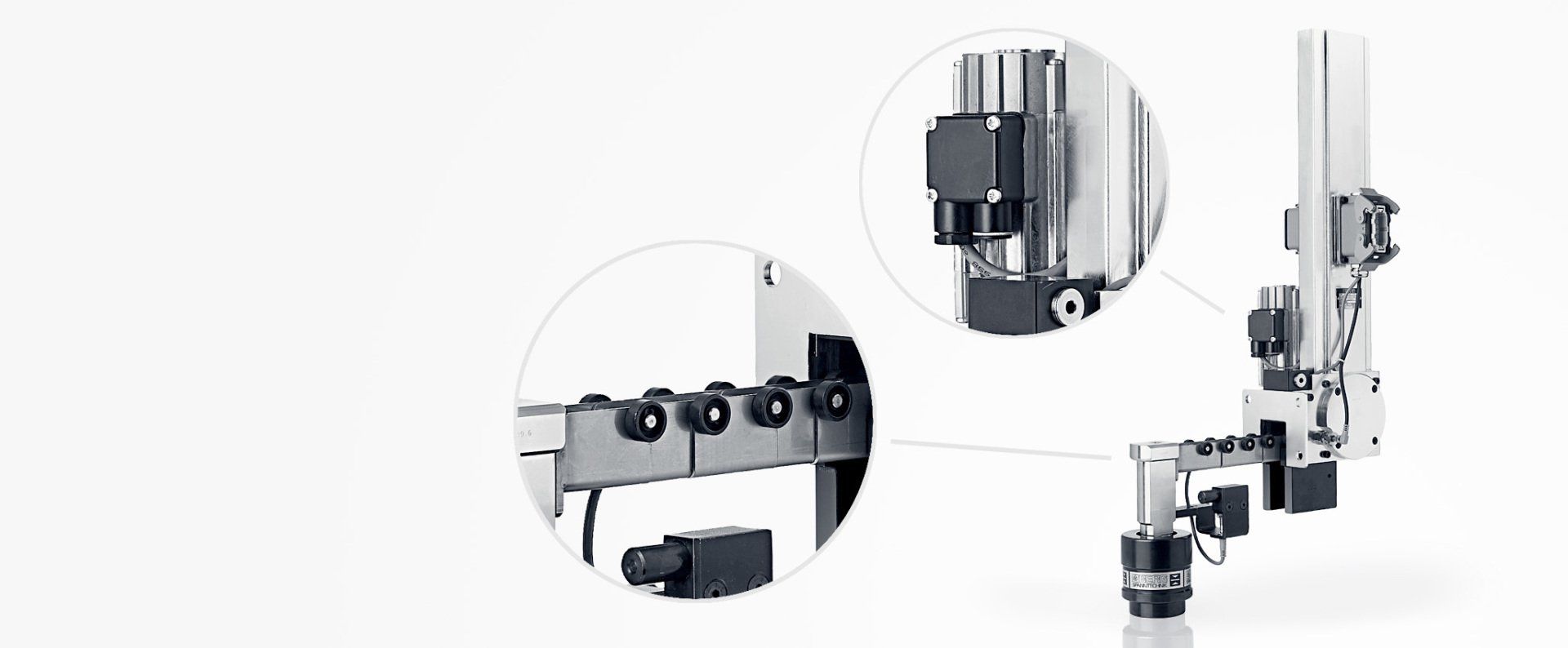

APPLICATION

Self-traveling, hydraulically operated clamping systems of type BKZ.../PSV enable die clamping on press slides with clamping slots regardless of the die width.

BENEFITS

- Essential functions electrically monitored

- Temperature-controlled motor

- Service-friendly modular unit

- Fast travel speed for highest productivity (> 100 mm/s)

- Service advice included by QR code

APPLICATION

Self-traveling and hydraulically operated clamping systems of type BKZ.../PKV are designed for die clamping on press slides with clamping slots regardless of the die width.

BENEFITS

- Essential functions electrically monitored

- Long-life rigid chain made of stainless steel

- Service-friendly modular unit

- Fast travel speed for highest productivity

- Service advice included by QR code

APPLICATION

Hydraulically operated, self-traveling clamping systems of type BKZ.../PKV-L are used for the automatic clamping of dies with clamping slots of various widths on press slides.

BENEFITS

- Fast travel speed for highest productivity

- Service advice included by QR code

- Essential functions electrically monitored

- Easy installation thanks to low weight

- Long-life rigid chain made of stainless steel

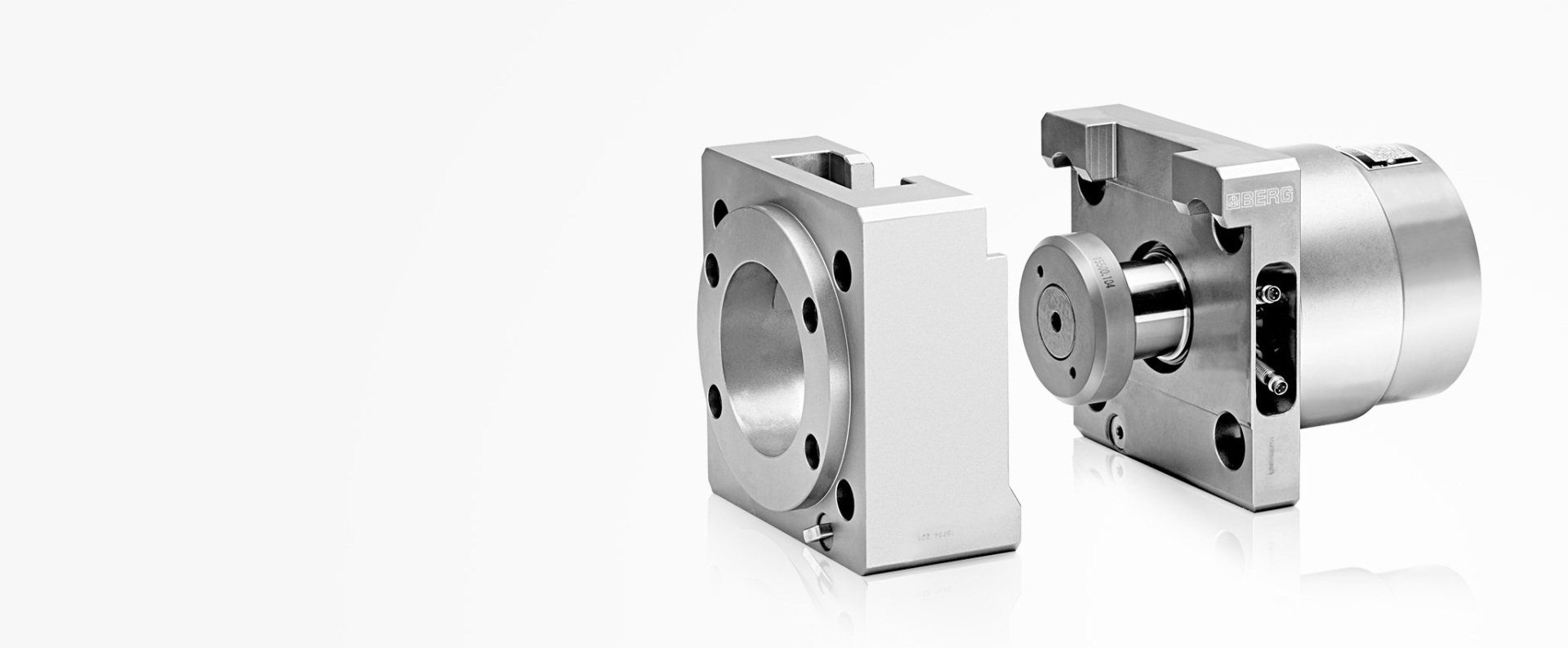

APPLICATION

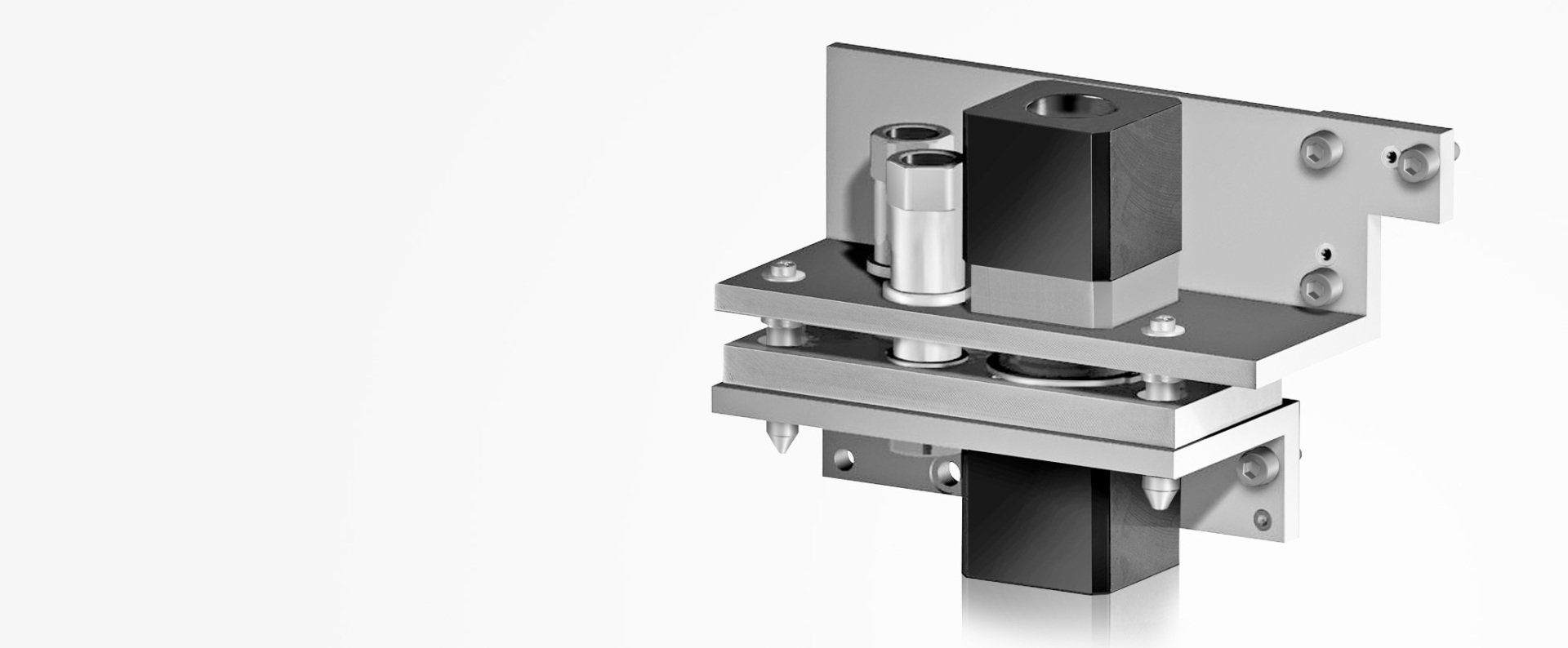

Transfer rail couplings of style GSE are electromechanical self-locking clamping systems specifically intended for use in transfer devices in forming machines.

BENEFITS

- Constant workpiece quality due to excellent centering accuracy and high clamping force

- Easy handling because of compact design with low mass

- High dynamic rigidity

- Easy to retrofit thanks to universal design

- High safety standard resulting from self-locking clamping gear and motor overload protection

APPLICATION

The electromechanical self-locking transfer rail coupling GSE-K with swiveling tension rod is designed for automatic coupling of transfer rails at forming machines.

BENEFITS

- Constant workpiece quality due to excellent centering accuracy and high clamping force

- Easy handling because of compact design with low mass

- High safety standard resulting from self-locking clamping gear and motor overload protection

- Easy to retrofit thanks to universal design

- Laid out for longest lifetime

APPLICATION

The electromechanical self-locking transfer rail coupling of type GSE-S…F is designed as a cartridge for mounting into the transfer rail. It is intended for automatic coupling of transfer rails at forming machines.

BENEFITS

- Constant workpiece quality due to excellent centering accuracy and high clamping force

- Highest cost effectiveness (no coupling counterpart needed)

- Ideal for retrofits thanks to universal cartridge design

- Great safety standard resulting from self-locking clamping gear and motor overload protection

- High dynamic rigidity with minimum mass

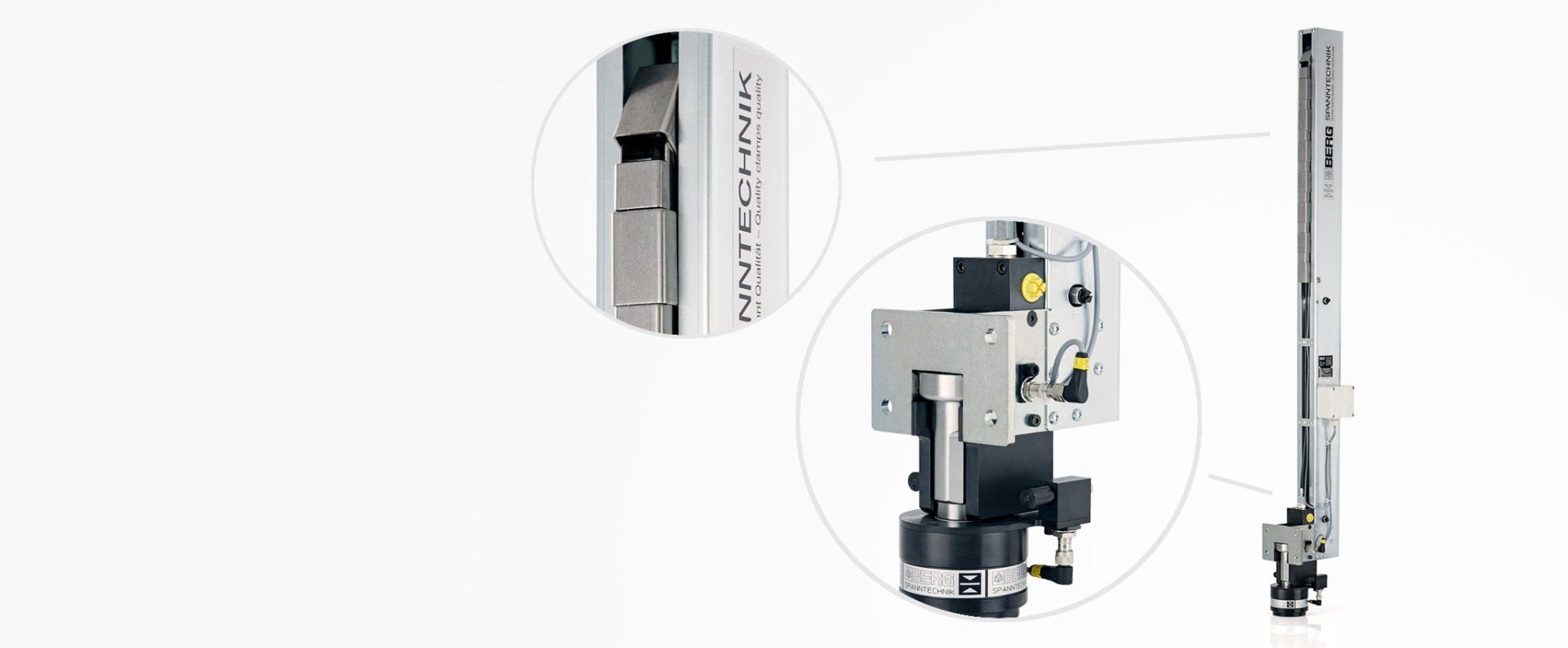

APPLICATION

Hydromechanical self-locking transfer rail couplings of style GSH are destined for automatic coupling of transfer rails at forming machines.

BENEFITS

- Constant workpiece quality due to excellent centering accuracy and high clamping force

- Compact design and wear-resistant light metal ensure easy handling

- High safety standard thanks to self-locking clamping gear

- Laid out for longest lifetime

- Easy to retrofit

APPLICATION

Hydromechanical transfer rail couplings of type GSH-S…F are intended for automatic coupling of axially driven transfer rails in transfer presses.

BENEFITS

- Constant workpiece quality due to excellent centering accuracy and high clamping force

- Easy handling because of compact design with low mass

- Highest cost effectiveness (no coupling counterpart needed)

- Ideal for retrofits thanks to universal cartridge design

- High safety standard resulting from self-locking clamping gear

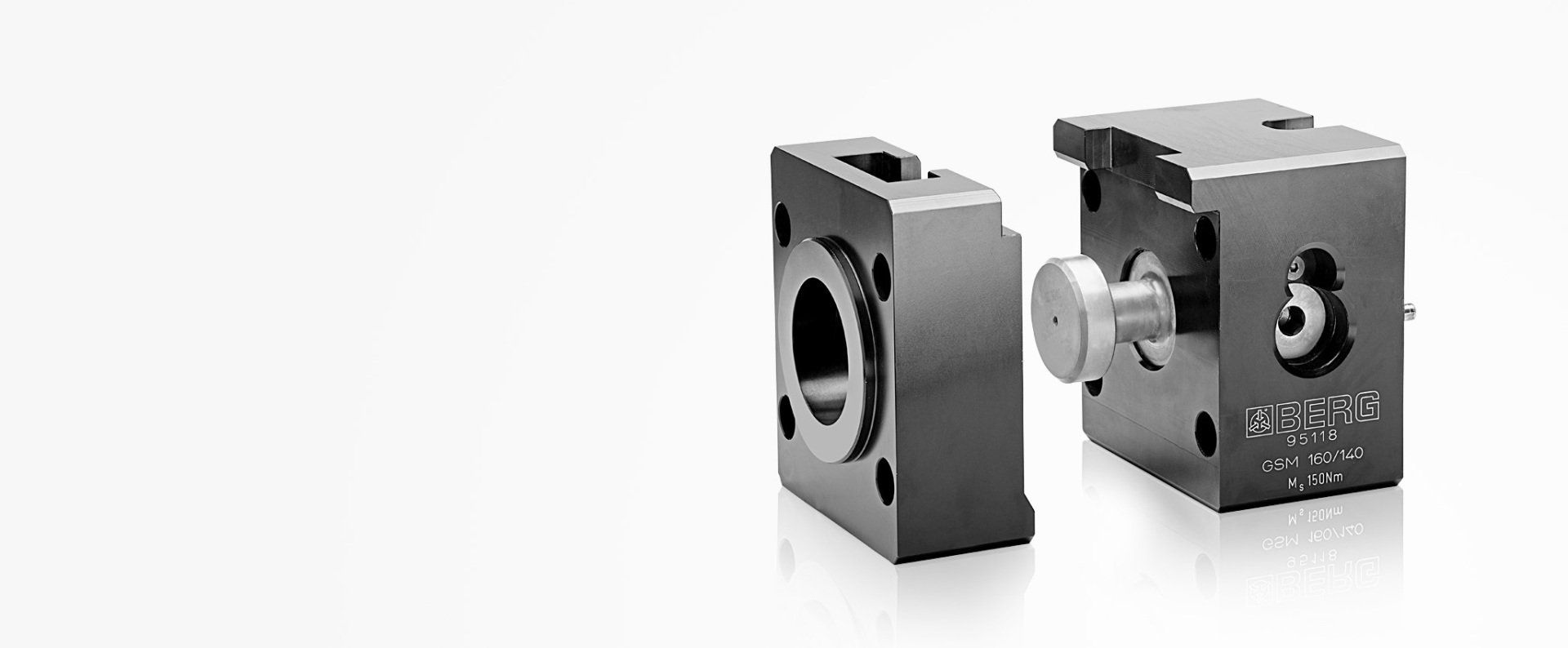

APPLICATION

The mechanical self-locking transfer rail coupling system GSM is designed for manual coupling of transfer rails at forming machines.

BENEFITS

- Constant workpiece quality due to excellent centering accuracy and high clamping force

- High dynamic rigidity with minimum mass

- Adaptable to existing rail profile

- Lowest installation costs

- No external energy supply needed

APPLICATION

The mechanical self-locking transfer rail coupling GSM-W with swiveling tension rod is suitable for manual coupling of transfer rails at forming machines.

BENEFITS

- Constant workpiece quality due to excellent centering accuracy and high clamping force

- High dynamic rigidity with minimum mass

- Adaptable to existing rail profile and different changing concepts

- Lowest installation costs

- No external energy supply needed

APPLICATION

The laterally mounted energy couplings are used for supplying electrical and pneumatic energy to exchangeable transfer rails at transfer presses.

BENEFITS

- Easy replaceable

- Design according to customer requirements

- Easy to retrofit

APPLICATION

PSP 300 HT are hydromechanical clamps configured to clamp moving bolsters with straight flanges in forming machines.

BENEFITS

- Space-saving due to compact design

- Minimum installation costs

- Fully controlled clamping process thanks to integrated proximity switches

- Integrated safety valve for good grade of safety

- Maintenance-free and robust clamp leads to low running costs

APPLICATION

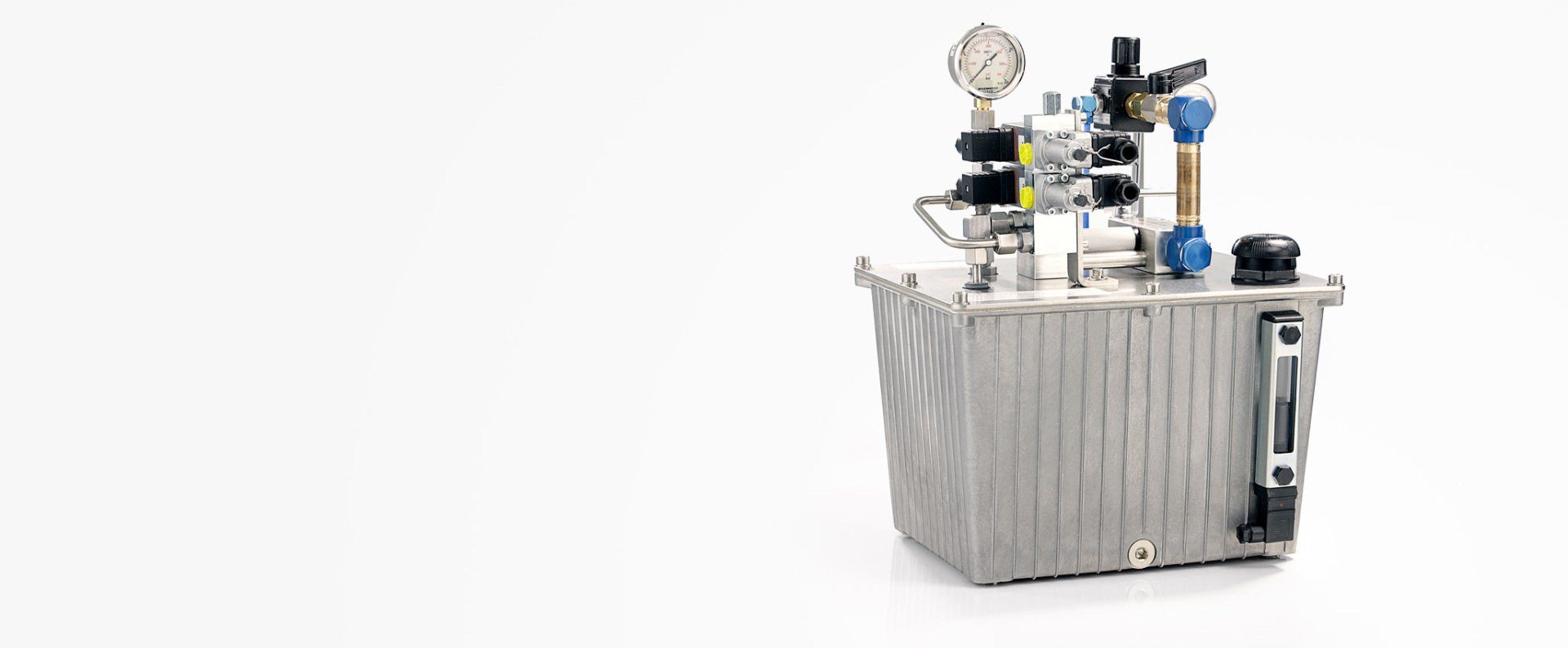

Air-hydraulic power stations like HAL 245/2/20 provide hydraulic oil for actuating hydraulic clamping elements in forming presses. Beside this system electro-hydraulic units are available (BERG product type HA 400/2/20).

BENEFITS

- Low installation expenses thanks to mounting option at press slide

- Easy usage (no high-voltage connection and no special control technology needed)

- Integrated pressure control

- Maintenance-free and laid out for long life

- Space-saving design